Manufacturers

- Abracon

- Adam Tech

- Aerospace, Defense & Marine

- Agastat

- AIC

- AKM Semiconductor

- Alcoswitch

- Allegro

- Alps Electric

- Altera

- AMI Semiconductor

- AMP

- ams

- Analog Devices (ADI)

- Aptina Imaging

- Atmel

- Avago / Broadcom

- AVX

- Axicom

- Bccomponents

- Beyschlag

- BI Technologies

- Bourns Inc.

- Bowei Integrated Circuits

- Bridgelux

- Buchanan

- California Micro Devices

- Catalyst Semiconductor

- CGS

- Cirrus Logic

- Citizen Electronics

- CML Microcircuits

- Coiltronics

- Cooper Bussmann

- Corcom

- Core Logic

- Cree

- CSR PLC

- CTS

- Cypress Semiconductor

- Dale

- Data Image

- Deutsch

- Diodes Incorporated

- DOMINANT Opto Technologies

- E-T-A

- Eaton

- ECS

- Edison Opto

- Elcon

- EPCOS

- Epistar

- Epson

- Everlight Electronics

- Exar

- Fairchild Semiconductor

- FCI

- Freescale Semiconductor

- Fremont Micro Devices (FMD)

- Fujitsu Semiconductor

- Fulltech Electric

- General Semiconductor

- Harvatek

- Holsworthy

- Hsuan Mao Technology

- IDT

- Infineon Technologies

- Innolux

- International Rectifier (IR)

- Intersil

- IRC

- ISSI

- IXYS-IC

- Jing Cheng Electronical

- JL World

- Johanson Dielectrics

- Johanson Technology

- JRC / NJR

- JST

- KEC

- Kilovac

- Kingbright

- Kyocera Industrial Ceramics

- LEDiL

- Linear Technology / ADI

- Lite-On Technology

- Littelfuse

- Lumex

- Lumileds

- Luminary Micro

- Luminus Devices

- Macronix

- Maojwei / ZJPT

- Maxim Integrated

- MCC

- Mean Well Enterprises

- Microchip Technology

- Micron

- Microsemi

- Mini-Circuits

- Molex

- Murata Manufacturing

- Murata Power Solutions

- MWT

- National Semiconductor

- Nichicon

- Nippon Chemi-Con

- NJR / JRC

- NVE

- NXP Semiconductors

- OEG

- Omnivision

- ON Semiconductor

- Optek Technology

- Optrex

- OSRAM Opto Semiconductors

- OTAX

- Panasonic

- Peregrine(pSemi)

- Potter & Brumfield

- Power Integrations

- PowerStor

- Preci-Dip

- Prewell

- Products Unlimited

- Pulse Electronics

- PulseCore Semiconductor

- Qorvo

- Raychem

- Renesas Electronics

- RFMD

- Richtek Technology

- ROHM Semiconductor

- Rubycon

- Samsung Electro-Mechanics

- Samsung Semiconductor

- Schaffner

- Schrack

- Seiko Instruments, Inc. (SII)

- Semtech

- Sensata

- Seoul Semiconductor

- Sfernice

- Sharp Display

- Sharp Microelectronics

- Silicon Labs

- Siliconix

- Skyworks Solutions

- SoniCrest / JL World

- Spansion

- Sprague

- Stanley Electric

- STMicroelectronics

- Sunny Electronics

- Susumu (SSM)

- Taimag

- Taiyo Yuden

- TDK

- TDK-Lambda

- TE Connectivity

- Teccor

- Texas Instruments (TI)

- Thin Film

- Tianma Micro-electronics

- TOCOS

- TOKO

- Toshiba Electronic Components

- TT Electronics

- Tusonix

- TXC

- Tyntek

- Vishay

- Vishay Precision Group

- Vitramon

- Walsin Technology

- Weidmuller

- Welwyn

- Wickmann

- Winbond

- Xilinx

- Yageo

- Zetex Semiconductors

- ZJPT / Maojwei

News

Toshiba’s IGBT/IEGT Compact Modeling Realizes Highly Accurate Prediction of Power Efficiency and EMI Noise

2019-06-14 | ReturnToshiba Electronic Devices & Storage Corporation

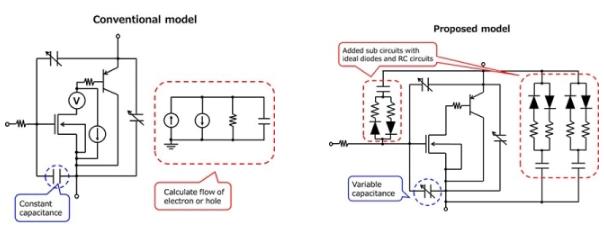

TOKYO -- Toshiba Electronic Devices & Storage Corporation has developed a compact model for highly accurate simulation and prediction of power loss and noise from electromagnetic interference (EMI) in Insulated Gate Bipolar Transistors (IGBT) and Injection Enhanced Gate Transistors (IEGT). The proposed model reproduces measured turn-on and turn-off switching waveform more accurately that current approached, and reduce the error rate by over 95% while cutting simulation time to less than one-thirtieth. [1]

Details were reported at the IEEE-sponsored International Symposium on Power Semiconductor Devices and ICs 2019 (ISPSD 2019) in Shanghai.

Power devices are essential components of inverter and converter circuits. IGBT and IEGT, which integrate MOS-gate control with bipolar conductivity modulation, are particularly important in high power applications, where they realize high input impedance and low on-resistance. Growth of the electric vehicle and renewable energy markets continues to drive forward demand for IGBT and IEGT.

In developing IGBT and IEGT, electron flow and hole flow are important considerations that produce complex switching performance. Accurate circuit simulation is essential to predict the power efficiency and EMI noise, as unpredicted EMI noise can damage the equipment, but conventional models do not sufficiently reproduce switching behavior. Increasing resistance in the circuit can damp EMI noise, but reduce the efficiency of the equipment.

Drawing on its extensive know-how in circuit modeling technology and world-class expertise in power devices, Toshiba has developed a new compact simulation model for IGBT and IEGT that realizes the accurate prediction of power-loss and EMI noise. It has two specific features.

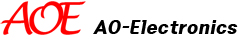

Two additional parallel sub circuits with an ideal diode and resistor and capacitor (RC) circuit reproduce switching. Conventional models can represent either hole or electron flow, but the sub circuits can represent both schematically, securing accurate prediction of the complex switching performance of bipolar transistors.

The proposed model also introduces a capacitor that shows change in capacitance over time. The conventional model uses a capacitor with stable capacitance regardless of voltage to transistors, but the capacitor in the proposed model is formed by a non-linear function that respond voltage change. This realizes an accurate prediction of EMI noise when switching.

Optimization of the circuit structure achieves a shorter simulation time for inductive load switching than the conventional model.

Toshiba will continue to improve accuracy of the proposed model and aim for its early utilization.

Notes

[1] Conventional and general models consists of current source and RC circuits. As of May 2019, Toshiba Electronic Devices & Storage Corporation.

Comparison of conventional and proposed model

Improved error detection rate

*Company names, product names, and service names may be trademarks of their respective companies.

Source:http://www.semicon.toshiba.co.jp/eng/